By Mychael Parker

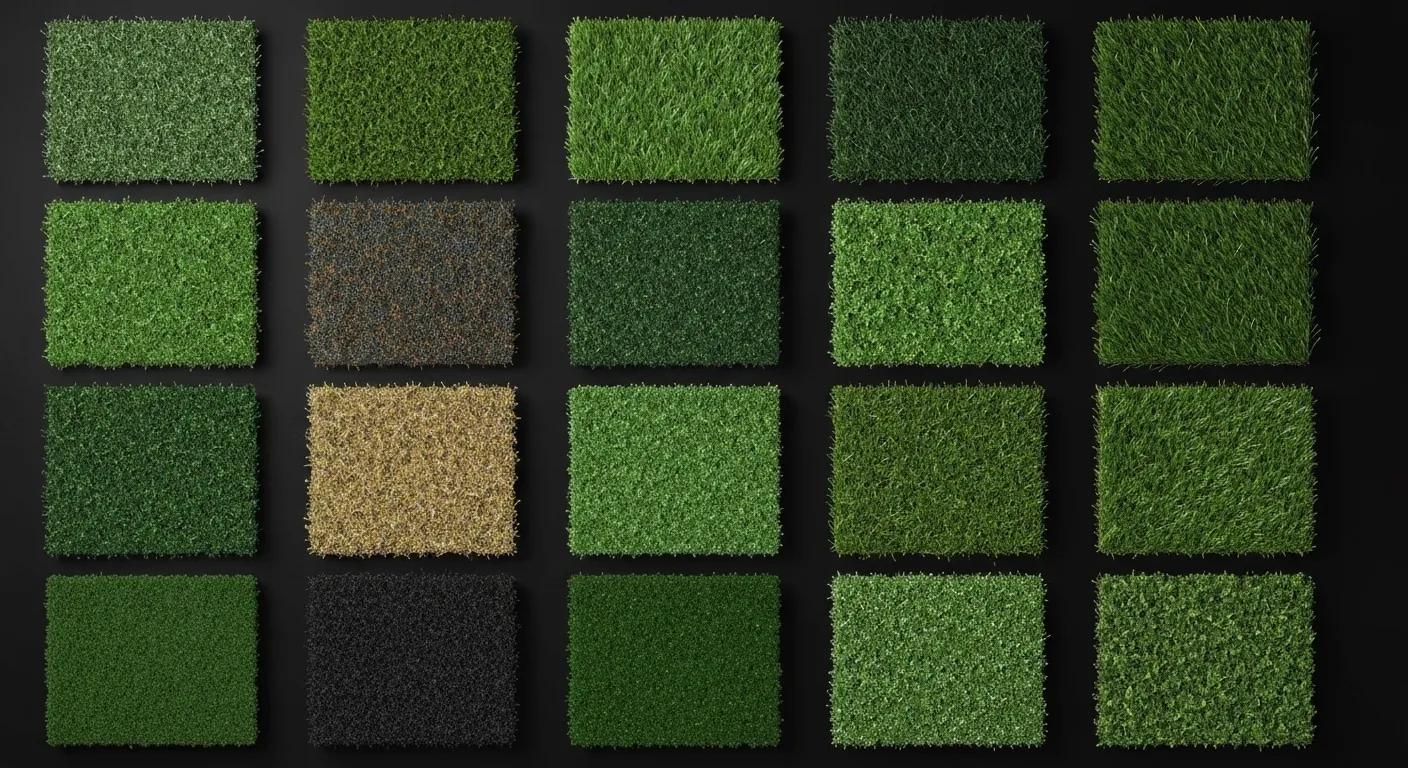

Artificial turf is a game-changer for water-wise landscaping in Phoenix, where intense sun and strict watering rules make durable synthetic grass a smart choice. Knowing the factors that shape wholesale turf prices in Phoenix helps landscapers, contractors, and facility managers budget with confidence. This guide breaks down the core elements: material quality, turf design, installation and extras, bulk buying benefits, special features, where it’s made, local market trends, getting the best return on investment, and common pricing questions. At Arturficial Wholesale, we’re experts in bulk artificial turf supply, guiding you through every cost factor to secure competitive rates without compromising on performance or lifespan.

The quality of materials you choose directly impacts your initial wholesale investment and the long-term value you receive. Higher-grade fibers and advanced backing systems come with a higher price tag but offer extended warranties and significantly less maintenance. The three fundamental aspects that form the basis of wholesale turf pricing are fiber composition, UV resistance, and the backing and drainage system.

The type of fiber used is a major driver of both price and performance in bulk turf orders. Polyethylene offers a great balance of softness and affordability. Polypropylene is a more budget-friendly option with decent wear resistance, while nylon commands a higher price for its superior resilience and ability to withstand heavy foot traffic.

| Fiber Type | Wholesale Price Range* | Durability Rating | Primary Benefit |

|---|---|---|---|

| Polyethylene | $1.50–$2.20 per sq ft | High | Soft feel, UV stability |

| Nylon | $2.30–$3.10 per sq ft | Very High | Exceptional resilience under constant load |

| Polypropylene | $1.20–$1.70 per sq ft | Moderate | Cost-effective entry-level turf |

When making wholesale purchases, it’s crucial to consider the initial fiber cost against the expected lifespan and the amount of foot traffic the turf will endure. This comparison highlights why matching the fiber composition to the intended application is so important before diving into design specifications.

Given Phoenix’s intense sunshine, UV resistance is absolutely vital. Ultraviolet stabilizers protect the turf fibers, preserving their color and tensile strength, but they do add about 10–20% to the wholesale cost.

Investing in UV-treated fibers means a higher upfront cost, but it guarantees fade-resistant turf that can handle Phoenix’s extreme climate, ultimately lowering the total cost of ownership through superior durability.

A strong backing system paired with an engineered drainage core increases manufacturing complexity, which in turn raises the wholesale unit price by 15–25%.

These advanced backing and drainage solutions justify a higher wholesale price by ensuring reliable installation and reducing potential site preparation problems. These structural elements pave the way for understanding turf design features like pile height and density.

The realism and resilience of turf are largely determined by its pile height and fiber density, which directly impact the amount of material used and the manufacturing costs. Bulk pricing reflects these design choices more than simple per-square-foot rates.

Pile height refers to the length of the blades. Premium options, typically 1.75–2.0 inches, command a 15–30% wholesale premium but provide a lush, natural look and feel underfoot.

Choosing the right pile height ensures your visual expectations align with your budget, and it naturally leads into considerations about fiber density.

Turf density, measured by stitches per square inch, is a key factor in both its lifespan and its price. Higher-density designs can increase wholesale costs by 10–20% but are better equipped to handle heavy use and keep the blades standing upright.

Adjusting the density ensures the turf can handle the required load without incurring unnecessary costs for excessive fiber volume.

The processes involved in color blending and texturizing add an element of craftsmanship, which in turn introduces incremental costs. Turf systems featuring multi-tone color blends and embossed blade textures can increase wholesale pricing by 5–15%.

| Turf Style | Color Options | Texture Detail | Price Impact |

|---|---|---|---|

| Single-tone green | One shade | Smooth blade | Base price |

| Dual-tone blend | Two complementary | Subtle embossing | +5–8% |

| Tri-tone blended | Three shades | Deep embossing | +10–15% |

These design enhancements contribute to a more realistic appearance for premium installations and naturally lead into the next crucial cost area: installation and associated expenses.

Installation and related site services often account for 30–50% of the total project cost. To budget accurately for wholesale purchases, you need to factor in demolition, grading, infill materials, and labor into your per-square-foot projections.

Thorough site preparation is essential for the longevity of your turf, but it can add $0.50–$1.20 per square foot to your project costs.

Proper preparation minimizes future maintenance issues and ensures a smooth transition to the infill and labor cost calculations.

The choice of infill—whether it’s sand, rubber crumb, or organic granules—affects both performance and wholesale pricing, adding $0.30–$0.80 per square foot.

| Infill Type | Cost per sq ft | Performance Attribute |

|---|---|---|

| Silica sand | $0.30–$0.40 | Stabilizes fibers, low cost |

| Crumb rubber | $0.50–$0.65 | Cushioning and resilience |

| Organic infill | $0.60–$0.80 | Eco-friendly, moderate shock absorbency |

Selecting the appropriate infill allows you to balance cost, comfort, and the specific application, setting the stage for the final labor cost considerations.

Labor rates for large-scale installations in Phoenix typically range from $2.00 to $4.50 per square foot, depending on the project’s complexity, site accessibility, and the crew’s experience level.

Understanding these labor cost drivers helps wholesale buyers reconcile the unit price of the turf with the total installed cost.

Economies of scale are a significant factor in wholesale artificial turf pricing. Larger orders typically unlock tiered discounts and reduce per-unit freight costs.

Many suppliers offer volume incentives, where reaching a certain order threshold triggers incremental savings.

Increasing your order volume secures better price breaks and lowers shipping costs per square foot.

The dynamics of bulk purchasing drive down unit prices through manufacturing efficiencies and consolidated freight shipments. For every additional 1,000 sq ft ordered, the landed cost typically decreases by 1–2%, making large-scale procurement more cost-effective.

Advanced turf systems designed for pets, enhanced cooling, or demanding sports applications involve additional manufacturing steps and material costs.

Pet-friendly turf incorporates antimicrobial backing and high-flow drainage cores, increasing wholesale costs by 8–12%. These features help prevent odors and ensure rapid liquid runoff.

Turf featuring reflective yarns and cooling infill blends can reduce surface temperatures by up to 25°F. These enhancements add 10–15% to bulk pricing but significantly improve comfort in both commercial and residential settings.

High-performance sports turf includes reinforced fibers, shock-padding layers, and shock-absorbent infill. These composite systems can increase unit costs by 20–35% but are engineered to meet the rigorous standards required for athletic venues.

Where turf is manufactured and the technologies used in its production influence material cost structures and the perceived quality of wholesale turf.

Manufacturing in the USA typically adds 10–20% to unit costs due to higher labor and compliance expenses. However, it also ensures consistent quality control, shorter lead times, and eligibility for local rebates.

State-of-the-art extrusion and fiber-texturing methods enhance blade resilience and color fidelity. Investment in proprietary machinery and research and development typically raises wholesale charges by 5–10% per square foot.

Phoenix’s regulatory landscape and rebate programs create unique cost considerations and requirements for bulk turf projects.

The City of Phoenix offers rebates of up to \$1,500 for residential conversions and provides unlimited funding for commercial properties that replace natural grass with synthetic surfaces. These incentives can cover 10–20% of total project expenses, effectively reducing the net cost of wholesale turf.

Arid conditions and extreme UV exposure demand higher concentrations of UV stabilizers and efficient drainage systems. Both of these features contribute to elevated wholesale pricing but are essential for ensuring longevity under the desert sun.

Municipal ordinances on water usage and the increasing demand for drought-tolerant landscaping drive innovation in eco-friendly turf options. This creates premium product tiers and competitive wholesale rates that are tailored to Phoenix’s growth trajectory.

Long-term savings on water, maintenance, and replacements transform synthetic turfinto a strategic investment for both commercial and residential property owners.

Artificial turf can reduce watering bills by up to 75%, cut landscaping labor costs by 60%, and eliminate expenses for aeration or reseeding. This typically results in a payback period of 3–5 years for large projects.

Partnering with an experienced wholesale provider like Arturficial Wholesale ensures access to volume incentives, quality-certified products, and expert installation guidance. This approach helps minimize hidden charges and protect your project margins.

Commercial developments in Scottsdale and Tempe have achieved annual savings of \$50,000–\$80,000 by switching from natural grass fields to high-density, UV-resistant turf. These results validate wholesale procurement strategies that prioritize long-term value.

Wholesale turf typically ranges from $1.50 to $4.00 per square foot, depending on factors like material quality, pile height, backing, and any specialized features.

The primary drivers include site preparation, infill selection, labor complexity, and site access logistics, which can account for up to 50% of the total installed cost.

Absolutely. Synthetic grass offers substantial savings on water and maintenance that more than offset the higher initial wholesale price over a 3–5-year lifecycle.

Residential grades start around $1.50 per sq ft, commercial mid-range options are typically $2.00–$3.00, pet-friendly systems average $2.50–$3.50, and premium sports turf can cost $4.00+ per square foot.

Artificial turf pricing in Phoenix varies significantly based on material quality, design specifications, installation factors, and market incentives. By understanding each cost driver—from fiber composition to water rebate programs—wholesale buyers can develop bids that effectively balance performance, longevity, and budget. Reach out to Arturficial Wholesale for personalized wholesale quotes, expert advice, and a partnership to create sustainable, water-wise landscapes throughout the Valley of the Sun.

artificial grass phoenix cost, wholesale turf prices, wholesale turf pricing, wholesale turf contractors tempe, factors influencing total project cost base work turf pad infill, how much does turf cost in arizona, 1 inch margins google docs, wholesale turf quote, artificial lawn cost phoenix

The fiber composition of artificial turf is a critical factor in determining its durability and cost. Polyethylene, nylon, and polypropylene are the most common fiber types used in wholesale turf. Polyethylene offers a soft feel and excellent UV stability, but nylon is more resilient and better suited for high-traffic areas. Polypropylene is a budget-friendly option with moderate wear resistance. Arturficial Wholesale

When making wholesale purchases, it's important to consider the initial fiber cost against the expected lifespan and the amount of foot traffic the turf will endure. Investing in UV-stabilized fibers may increase the upfront cost, but it ensures long-lasting performance in Phoenix's intense sunlight. Arturficial Wholesale

The realism and resilience of artificial turf are largely determined by its pile height and fiber density. Premium options with taller pile heights (typically 1.75-2.0 inches) provide a lush, natural look and feel, but they also come with a 15-30% wholesale premium. Turf density, measured by stitches per square inch, is another key factor that impacts both lifespan and price. Arturficial Wholesale

In addition to fiber characteristics, the backing and drainage system of the turf can also influence the wholesale price. A stronger backing and engineered drainage core increase manufacturing complexity, resulting in a 15-25% higher unit cost. Balancing these specifications with your budget is crucial to achieve the desired performance and visual appeal. Arturficial Wholesale

When budgeting for wholesale artificial turf purchases, it's essential to factor in the costs associated with site preparation, infill materials, and labor. Proper site preparation, including demolition, grading, and drainage, can add $0.50-$1.20 per square foot to the project. The choice of infill, such as sand, rubber crumb, or organic granules, can also impact performance and pricing, ranging from $0.30-$0.80 per square foot. Arturficial Wholesale

Labor costs for large-scale commercial installations in Phoenix typically range from $2.00 to $4.50 per square foot, depending on the project's complexity, site accessibility, and the crew's experience level. Understanding these ancillary costs helps wholesale buyers develop accurate budgets and make informed purchasing decisions. Arturficial Wholesale

Arturficial Wholesale offers volume incentives to help wholesale buyers maximize cost savings. Reaching certain order thresholds can trigger discounts of up to 15% off the base price. For every additional 1,000 square feet ordered, the landed cost typically decreases by 1-2%, making large-scale procurement more cost-effective. Arturficial Wholesale

In addition to bulk discounts, Arturficial Wholesale also helps customers identify and take advantage of local water conservation rebates and other incentive programs, which can cover 10-20% of the total project expenses. By partnering with an experienced wholesale provider, buyers can benefit from these cost-saving opportunities and ensure a favorable return on their turf investment. Arturficial Wholesale