By Mychael Paker

For any substantial landscaping project, sports complex, or pet-friendly zone, a dependable, cost-effective artificial grass distributor is essential for sourcing premium synthetic grass in bulk. This guide is designed to equip contractors, landscapers, facility managers, pet-area specialists, and business owners with the insights needed to compare turf materials, capitalize on wholesale pricing, navigate installation and upkeep, explore commercial uses, evaluate eco-friendly advantages, and ultimately pinpoint the ideal distributor for seamless project execution. You’ll gain clarity on:

Artificial turf distributors offer a comprehensive selection of synthetic grass options, differentiated by their fiber composition, pile height, backing technology, and unique features. Understanding the specific attributes of each turf type is crucial for selecting the optimal product for performance, aesthetics, and longevity in any large-scale project.

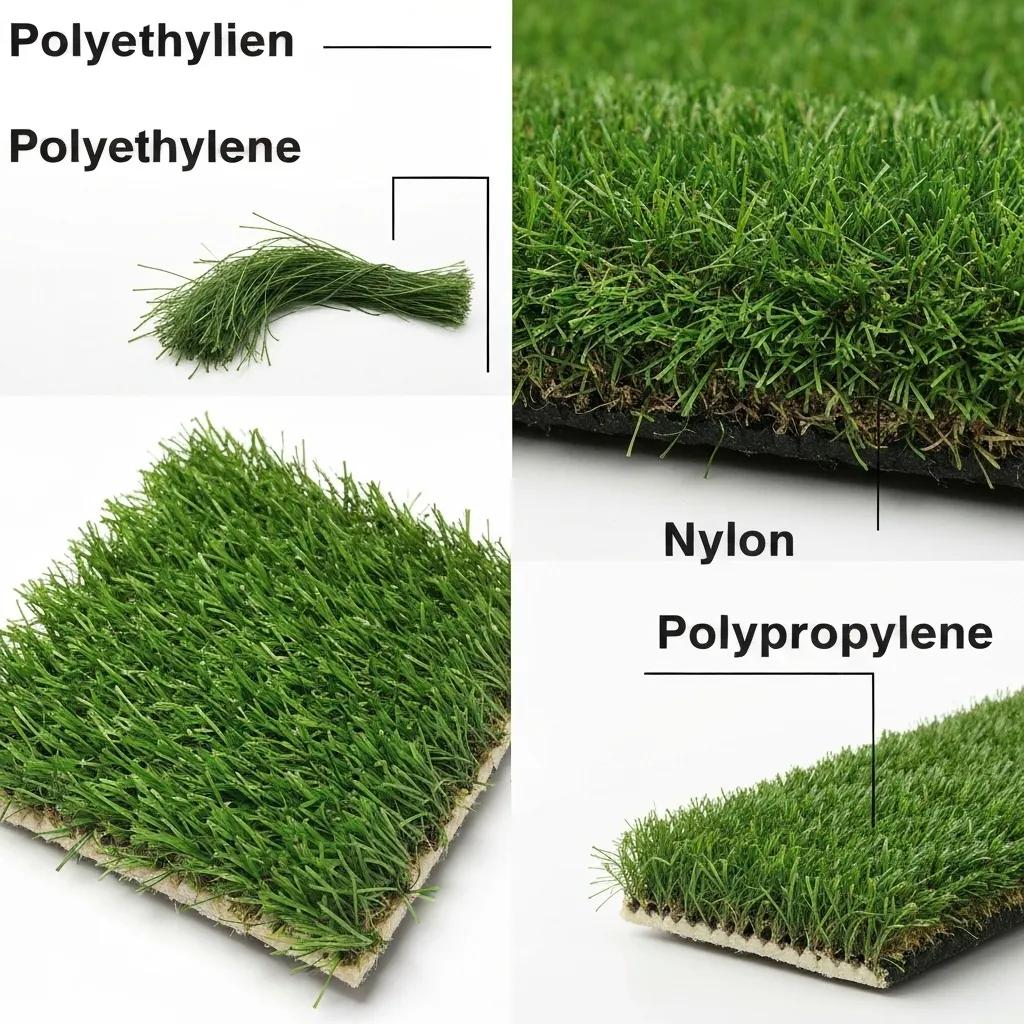

Below, we break down the three primary turf fiber materials, detailing their durability, softness, and cost to help guide your selection for diverse applications.

| Turf Material | Durability Rating | Softness & Aesthetics |

|---|---|---|

| Polyethylene | Highly resilient for high-traffic zones, featuring UV-stable coating | Offers a plush, natural, grassy feel with rich color retention |

| Nylon | Exceptional wear resistance, engineered for extreme load conditions | Provides a stiffer texture, ideal for sports applications requiring consistent ball roll |

| Polypropylene | Moderate strength, suitable for low-impact areas | An economical choice with a basic appearance and lower fabric density |

This material overview clarifies how substance choice impacts performance and user experience, naturally leading into a discussion of hybrid and specialty turf innovations.

Hybrid and niche turf blends incorporate multiple polymers, fire-retardant additives, or antimicrobial treatments to meet specialized project demands:

These advanced product offerings ensure tailored solutions for unique project requirements while maintaining the cost efficiencies associated with wholesale procurement.

Selecting the optimal turf variant depends on its intended use, expected foot traffic, and desired maintenance profile:

| Application | Recommended Turf | Key Attribute |

|---|---|---|

| Commercial Landscape | Polyethylene with a 1.5″ pile height | Requires minimal upkeep and delivers an upscale appearance |

| Sports Fields | Nylon-reinforced or hybrid constructions | Offers superior resilience and consistent ball roll characteristics |

| Pet Areas | Polyethylene with antimicrobial backing | Ensures rapid drainage and effective odor control |

Matching product specifications precisely to the end-use guarantees project success and facilitates a smooth transition into leveraging bulk purchasing advantages.

Purchasing synthetic turf in volume significantly reduces the per-unit cost, with tiered pricing structures based on volume breaks:

By strategically utilizing these bulk pricing tiers, businesses can improve project margins and maintain competitive bids on high-volume installations.

Securing large quantities of turf in a single order guarantees consistent fiber batch production, uniform pile density, and reliable backing integrity. Leading distributors proactively manage inventory forecasts and schedule timely replenishment to prevent supply disruptions, ensuring uniform turf appearance and performance across expansive sites.

Professional wholesale partners complement their competitive pricing with a suite of tailored support services:

These comprehensive support services streamline the procurement process and empower installers to execute large-scale projects with confidence and efficiency.

Sports turf engineered for professional play features high-density substance arrays, reinforced backing systems, and shock-absorbing infill. These critical components enhance ball roll consistency, improve abrasion resistance, and prioritize athlete safety, ensuring the turf can withstand the rigors of constant practice and competitive matches.

Pet-rated turf solutions are designed with quick-drain backings, antimicrobial yarns, and odor-neutralizing infill. Liquids and waste pass through specialized perforations into a permeable sub-base, effectively preventing puddles and odor buildup while facilitating easy rinse-and-clean maintenance routines.

For corporate complexes, retail plazas, or hospitality venues, synthetic turf offers exceptional curb appeal without the ongoing costs of irrigation, mowing, or fertilization. Its consistent, year-round green appearance reinforces brand professionalism while freeing up maintenance budgets for core business operations.

Forward-thinking Phoenix designers and builders are adopting modular turf panels for innovative applications such as vertical gardens, acoustic dampening solutions, and overhead shading structures. Indoor batting cages utilize specialized turf with integrated traction fibers to accurately simulate field conditions. These niche uses highlight the remarkable versatility of synthetic grass beyond traditional horizontal landscaping applications.

Follow these fundamental steps to ensure a successful synthetic grass installation on a properly compacted, stable base:

| Installation Step | Tool/Material | Purpose |

|---|---|---|

| Sub-Base Compaction | Plate compactor | Establishes a stable, drainage-ready foundation |

| Seam Taping | Seaming tape & adhesive | Creates invisible, strong seams between turf sections |

| Infill Application | Drop spreader & brush broom | Ensures proper blade stand and optimal shock absorption |

Meticulous adherence to each phase guarantees seamless integration of drainage, stability, and fiber resilience for a long-lasting installation.

Adequate outflow is achieved through a combination of perforated turf backing, a precisely graded aggregate sub-base, and, in some cases, integrated French drains. Liquids pass through the turf backing into the crushed stone layer and then flow into a sub-surface collection system. This layered design accelerates water runoff, prevents surface pooling, and maintains a dry, usable surface even under heavy use.

Selecting the appropriate infill material is key to optimizing cushion, stability, and overall performance:

| Infill Material | Characteristic | Performance Benefit |

|---|---|---|

| Silica Sand | Dense and cost-effective | Provides excellent fiber stabilization and supports foot traffic |

| Rubber Granules | Shock-absorbent and elastic | Enhances athlete safety and user comfort |

| Coated Sand Mix | Features an antimicrobial coating | Helps control odors and inhibit bacterial growth |

Thoughtful infill selection ensures the turf’s properties align perfectly with expected traffic patterns and usage intensity.

Regular maintenance, including brushing to restore fiber orientation, debris removal, spot rinsing, and periodic infill top-ups, is essential for preserving turf uniformity and maintaining the upright posture of the fibers. Schedule quarterly inspections to check seam tension, trim any loose edges, and refresh infill levels, thereby extending the supplier warranty and maximizing the turf’s lifespan.

Artificial turf completely eliminates the need for water/irrigation, potentially saving up to 55,000 gallons of water per acre annually. Its recyclable backing and non-toxic yarns minimize environmental impact, and the absence of pesticides or fertilizers promotes eco-friendly site stewardship.

Commercial-grade turf sold in bulk typically comes with warranties ranging from 10 to 15 years, covering UV degradation, backing failure, and excessive wear. Reinforced stitch rates and advanced polymer blends ensure the turf maintains its resilience under continuous foot or vehicle traffic.

Synthetic grass significantly reduces annual maintenance expenses by eliminating the costs associated with mowing, fertilizing, aeration, and irrigation labor. Over 10 years, the savings generated often exceed twice the initial artificial grass investment, offering a substantial return on investment for commercial landscaping budgets.

The consistent color, fabric density, and blade texture of synthetic grass lend commercial landscapes a perpetually vibrant and polished appearance. Customizable pile heights, mixed-tone yarns, and decorative infill options provide extensive design flexibility, allowing for the reinforcement of brand imagery and enhanced customer appeal.

Thoroughly evaluating these key criteria will help you secure a partner whose offerings align perfectly with your project’s performance and budget requirements.

Dedicated programs often include volume discounts on turf accessories, priority shipping arrangements, valuable training resources, and collaborative co-marketing opportunities. Such strategic partnerships effectively reduce project risks and foster long-term relationships conducive to securing repeat large-scale work.

Distributors typically manage Less Than Truckload (LTL) or Full Truckload (FTL) freight, maintain regional warehousing facilities, and offer just-in-time delivery services. Palletized shipments simplify unloading and on-site staging, while direct drop-ship services enable delivery to multiple job sites, thereby reducing handling costs and minimizing scheduling delays.

Wholesale artificial grass offers substantial per-unit cost reductions, but it requires higher minimum order quantities and includes tailored logistics support. Retail purchases are generally suited for smaller residential needs, featuring fixed roll lengths and standard product lines. In contrast, wholesale distributors offer greater volume flexibility, specialized fabric grades, and project-specific service levels.

Both pet-friendly and athletic artificial grass installations incorporate high-permeability backings and precisely graded aggregate underlayers designed to rapidly channel liquids away from the surface. Pet Turf installations prioritize antimicrobial infill and enhanced odor control, while sports fields may integrate subsurface pipe networks to manage heavy rainfall and maintain optimal playability.

Three primary polymers are predominantly used in synthetic turf manufacturing:

Hybrid blends skillfully combine these fibers to optimize aesthetics and durability for specific use cases and performance demands.

Consistent upkeep involves regular brushing to restore fabric orientation, rinsing to remove surface debris, spot-cleaning any stains promptly, and replenishing infill to maintain optimal cushion and support. Annual inspections of seams, edges, and backing integrity are crucial to ensure manufacturer warranties remain valid and the turf continues to perform effectively under heavy use.

Wholesale artificial grass distribution empowers professionals to achieve consistent quality, competitive pricing, and expert support for projects of any scale. By thoroughly understanding material options, installation techniques for fake sod, maintenance routines, and environmental advantages, you can confidently partner with a distributor that delivers large-volume turf solutions reliably, on time, and within budget.

what does polyethylene look like, turf distribution, soccer tape, artificial turf distributor, turf distributors reviews

As an artificial turf distributor, you can offer your customers a wide range of benefits, including cost-effectiveness, quality assurance, and expert support. By leveraging wholesale pricing and large-volume purchasing power, you can provide your clients with premium synthetic grass products at competitive rates. Additionally, you can ensure consistent quality and reliability through centralized inventory management and streamlined logistics. Arturficial Wholesale

Partnering with a reputable artificial turf distributor like Arturficial Wholesale also grants access to valuable resources, such as installation guidance, maintenance protocols, and project-specific support. This enables your customers to execute their landscaping, sports, or pet-friendly projects seamlessly, maximizing the long-term performance and durability of the synthetic grass. Arturficial Wholesale

Artificial turf distributors offer a diverse selection of synthetic grass options, each with its unique fiber composition, pile height, and backing technology. Understanding the performance attributes of these materials is crucial for selecting the optimal product for specific applications, such as commercial landscaping, sports facilities, or pet areas. Arturficial Wholesale

The three primary fiber types used in artificial turf are polyethylene, nylon, and polypropylene. Polyethylene is known for its resilience and natural-looking appearance, making it suitable for high-traffic commercial landscapes. Nylon, on the other hand, is engineered for extreme load conditions, providing exceptional wear resistance and consistent ball roll characteristics for sports fields. Polypropylene is an economical choice for low-impact areas, offering moderate strength and a basic aesthetic. Arturficial Wholesale

Beyond the standard fiber types, artificial turf distributors also offer hybrid and niche products to meet specialized project demands. These innovative turf blends combine multiple polymers, fire-retardant additives, or antimicrobial treatments to enhance performance and functionality. For instance, multi-substance constructions can leverage the softness of polyethylene and the strength of nylon, while pet-friendly turf may feature quick-drain backings and odor-neutralizing infill. Arturficial Wholesale

The selection of the optimal artificial turf variant depends on the intended application, expected foot traffic, and desired maintenance profile. Commercial landscapes, sports fields, and pet areas each have unique requirements that can be addressed through the appropriate turf specifications. Arturficial Wholesale

Securing large quantities of artificial turf through wholesale distribution offers numerous advantages, including consistent quality, reliable availability, and access to essential installation accessories. By ordering in bulk, customers can ensure uniform fiber batches, pile density, and backing integrity, which are crucial for achieving a cohesive and long-lasting installation. Arturficial Wholesale

In addition to the turf itself, wholesale distributors can provide a comprehensive suite of installation tools, seam tape, adhesives, and infill materials. This streamlines the installation process and ensures that all necessary components are readily available for seamless project execution. Proper adherence to installation best practices, such as sub-base compaction, seam taping, and infill application, is essential for maximizing the performance and longevity of the synthetic grass. Arturficial Wholesale